Hello and welcome to LongKou Hongrun Packing Machinery Co.,LTD

中文版 | English | العربية | русский | español | português | françaishrmachine@lkhrmachine.com

Hello and welcome to LongKou Hongrun Packing Machinery Co.,LTD

中文版 | English | العربية | русский | español | português | françaisFull-auto Forming and Cutting Machine

PS Foam Sheet Extrusion Machine

PS Foam Material Recycle Machine

EPE Foam Sheet Extrusion Machine

EPE Foam Material Recycle Machine

Longkou City Hongrun Packing Machinery Co., Ltd.

Address: Zhuyou Industrial Zone ,Longkou City , Shandong Province ,China

Zip Code:265705

E-mail:hrmachine@lkhrmachine.com

Mobile: +86 15552447686

Tel: +86 535 8573288

Fax: +86 535 8573866

EPS Foam Cup Making Machine

EPS Foam Cup Making MachineFeatures of eps cup machine 1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing . 2. Light weight, good rigidity and we

EPS Foam Cup Making Machine

Features of eps cup machine

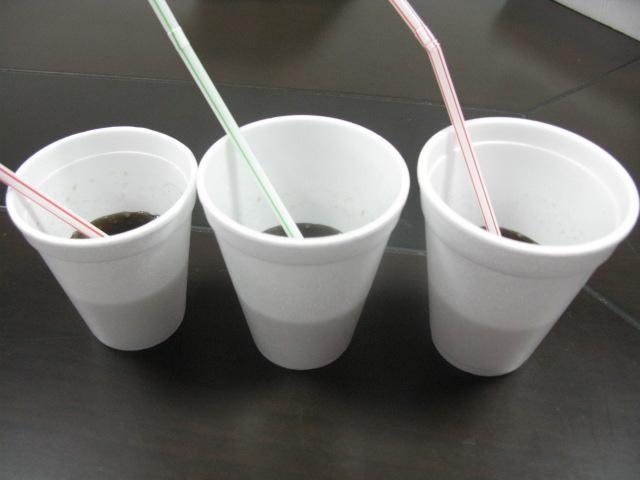

1. EPS Foaming-Cup Production Line is widely applied in producing large amount of hot coffee cup, hot tea cup, hot soup blow, noodle tub and other food and beverage packing .

2. Light weight, good rigidity and well heat isolation.

3. The machine holds many merits such as high foaming times, high producing efficiency, low steam consumption, low cost and different model products are made at same time.

4. Pipes and tubes of the transferring system are all made from stainless material so that they resist eroding and easy to be cleaned.

5. Pre-expand and forming procedures are all operated by automatic controller, the mechanical and electrical device or apparatuses are all from international famous brand

| Main Items | Description | |

| Cup Size | 6~16 Oz | |

| Cavity No. | 6~8 Pcs | |

| Production Cycle | 6~16 seconds/cycle | |

| Power Consumption | 300 W (Forming Machine) | |

| Primary Configuration | Item | Description |

| 1. Raw Material Mixer and Feeding Device | Voltage | 380V(220V), 50Hz |

| Motor | 3Kw, 960Rpm | |

| Mix | 350Kg/time | |

| 2. Pre-Foaming Machine | Steam press | 0.7-0.8MPa |

| Air press | 0.7-0.8MPa | |

| Foaming time | 20-50Seconds/cycle | |

| Output | 50-160Kg/h | |

| Motor | 3Kw | |

| Machine size (L*W*H) | 1400*800*2500mm | |

| 3. Drying Machine | Output | 150-200Kg/h |

| Motor | 6.6Kw | |

| Machine size (L*W*H) | 2800*600*1100mm | |

| 4. Vibration Machine | Output | 50-200Kg/h |

| Motor | 1.5Kw | |

| Machine size (L*W*H) | 1100*1000*1000mm | |

| 5. Centre filling device | Motor | 2.2Kw, 3 sets |

| Big hopper | 1500*1500*450mm, 3 sets | |

| Small hopper | 1200*1000*1000mm,1 set | |

| Material stock bag | 1000*1000*1200mm | |

| 6. Forming Machine | Stroke height | 3-180mm |

| Production cycle | 6-16seconds/cycle | |

| Energy consumption | ≤0.3Kw | |

| Steam press | 0.6-0.9MPa | |

| Cooling water press | 0.4-0.5MPa | |

| Air press | 0.6-0.9MPa | |

| Working area (L*W) | 1200*280mm | |