Hello and welcome to LongKou Hongrun Packing Machinery Co.,LTD

中文版 | English | العربية | русский | español | português | françaishrmachine@lkhrmachine.com

Hello and welcome to LongKou Hongrun Packing Machinery Co.,LTD

中文版 | English | العربية | русский | español | português | françaisFull-auto Forming and Cutting Machine

PS Foam Sheet Extrusion Machine

PS Foam Material Recycle Machine

EPE Foam Sheet Extrusion Machine

EPE Foam Material Recycle Machine

Longkou City Hongrun Packing Machinery Co., Ltd.

Address: Zhuyou Industrial Zone ,Longkou City , Shandong Province ,China

Zip Code:265705

E-mail:hrmachine@lkhrmachine.com

Mobile: +86 15552447686

Tel: +86 535 8573288

Fax: +86 535 8573866

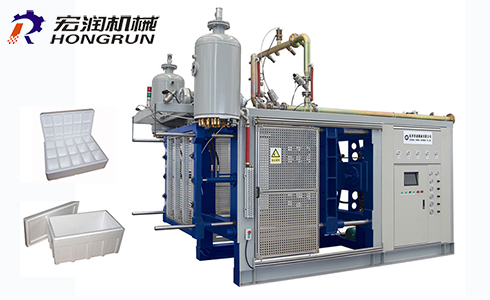

EPS Shaping Moulding Machine

EPS Shaping Moulding MachineThe machine applies PLC and touch screen with advanced molding technique can produce various shapes of EPS products, the vacuum and hydraulic system can increase molding speed and reduce cooling time, the cold condenser and energy saving pi

The machine applies PLC and touch screen with advanced molding technique can produce various shapes of EPS products, the vacuum and hydraulic system can increase molding speed and reduce cooling time, the cold condenser and energy saving pipes structure saves a lot of steam and electricity.

Main Feature:

1, combined with the high-quality characteristics of Europe, Japan and China Taiwan and other models, widely used;

2, molded foam products with low water content, low energy consumption of equipment, short production cycle, product size and stability;

3 interchangeable types of mold, equipment compatibility, saving tooling costs;

4, the frame is welded steel hollow shape, high strength, good stability;

5, after the failure of high-temperature annealing chassis welding heat treatment, the use of imported CNC machining center, bottom fine sand-blasting, galvanizing and overall surface paint, high corrosion resistance;

6, using advanced multi-cylinder hydraulic clamping systems, clamping fast, strong clamping;

7, the use of advanced central energy distributor, the equilibrium vapor pressure stable;

8, high-efficiency vacuum cooling with a spray nozzle, independent drainage system, greatly reducing the vacuum time;

9, pressure feed, advanced sensors to control quantity and density;

10, fully automatic computer control system, color touch-screen control, simple operation;

Technical Parameter:

| DES |

Unit/ item |

HR500 | HR900 | HR1300 | HR1500 | HR2000 |

| Mold size | mm | 1200×1000 | 1400×1200 | 1600×1350 | 1800×1530 | 2000×1750 |

| Product size | mm | 1060×810×300 | 1230×1030×300 | 1480×1180×300 | 1560×1360×300 | 1780×1580×300 |

| Mold open distance | mm | 200-1300 | 200-1300 | 200-1300 | 200-1300 | 200-1300 |

| Steam consumption | Kg/cycle | 7 | 9 | 10 | 11 | 13 |

| Vacuum pump capacity | m3/h | 165 | 230 | 280 | 180 | 280 |

| Power | KW | 11 | 13.5 | 16 | 19.6 | 23 |

| Outsize | mm | 4850×1860×3900 | 5100×2160×4000 | 5300×2250×4200 | 5400×2550×4600 | 5500×2800×4850 |

| Weight | kg | 4150 | 4300 | 4500 | 5000 | 6800 |